The only wholesale factory of all resistance bands

The resistance band includes loop band, sheet band, tube band. Different shapes of resistance band require different techniques to manufacture. HQ Rubber is the only factory that can manufacture Power Band, Mini Band, Tube Band, Flat Band and Fabric Band in-house. This will provide the color, strength, finish and consistency of the entire resistance band line.

Origin Resistance Band Factory starting 1996

Beginning in 1996, the construction of our headquarters facility began with handcrafted latex balls and bladders. Our goal is to utilize the material properties of natural rubber latex to produce safe, recyclable, high-strength, highly-sealed and trustworthy rubber products. We have more than 20 experienced engineers, we can customize the performance of the resistance bands according to the customer’s requirements, such as: colors, hardness, performance, feel, appearance, etc.

Resistance Band Family

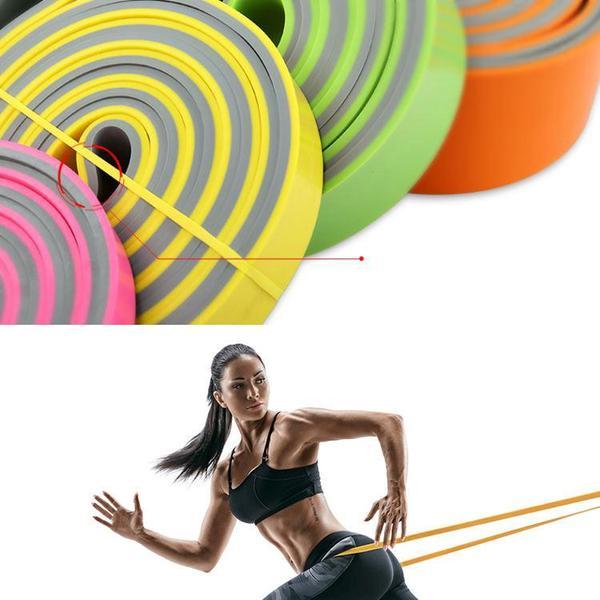

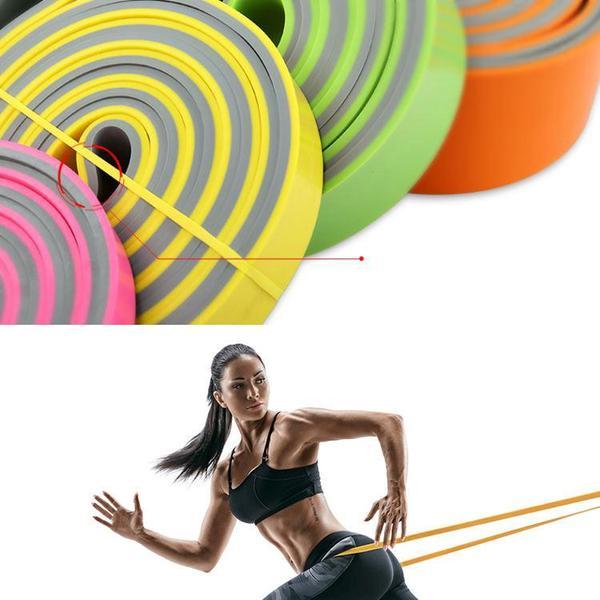

Dual Layers Power Band

Grid Mini Loop Band

Power Mini Loop Band

Flat Resistance Band

Floss Band

Tube Resistance Band

Booty Resistance Band

Contact Wholesale Resistance Band Vendor!

Best Resistance Band Process Line

From manual craftsmanship to now Industry 3.0, HQ Rubber has developed the world’s only automatic dipping line, resistance tube extrusion line. Automatic resistance band processing line provides stable resistance band quality such as constant thickness, color, strength and durability.

Resistance Band Factory Quality Control

From raw material to finished product, we have more than 7 inspection procedures to ensure that all bands are inspected so as not to cause harm to the trainer during useage. Our quality control follows ISO9001 and can meet Decathlon, Walmart and Target quality protocols.

Raw Material Testing

Our raw materials are born naturally. In our resistance band factory, each raw material batch is tested for liquefaction, concentration, pH and stability to ensure the raw material is suitable for use.

Mix Process

Mixing the latex rubber with the vulcanizing agent takes 48 hours to ensure the material is fully prepared before molding. In order to guarantee the mixing process of the material, it is checked every 6 hours until it is mature. Process is done in factory.

Chemical Test in Factory

After the resistance bands are shaped and cooked, we do a chemical check to make sure the resistance bands are ripe. A well-designed resistance band will provide optimal resistance and good durability. Immature resistance bands run the risk of broken or unstable resistance.

Compliance and Performance Test

All our resistance bands have passed US and UK compliance tests such as RoHS, Reach and Pro65. All bands are performance tested before shipping to customers, testing include strength, repeated cycles of regression usage.

Resistance Band Family

Dual Layers Power Band

Grid Mini Loop Band

Power Mini Loop Band

Flat Resistance Band

Floss Band

Tube Resistance Band